Helios presents the principal technology platform for our RoboCoat system, a joint venture formed between Remotion AS and Aker BP.

Concern about microplastic pollution in our oceans has been growing globally. Consequently, numerous authorities have tightened plastic emission rules. The offshore surface treatment operations are among those affected by the new regulations.

The team here at Remotion embarked on a mission to address this problem. The goal was to develop a remotely operated, efficient and complete surface treatment system with zero emissions to the natural environment. The solution should work independently without interrupting offshore installations’ production and daily working routines.

In response to these requirements, Remotion engineers invented the RoboCoat system. The robot removes old coating and grit blast and then repaints the surface without emitting paint or grit residues into the environment. The vessel operations remain uninterrupted during the entire process. Moreover, the technology is much more efficient than traditional methods.

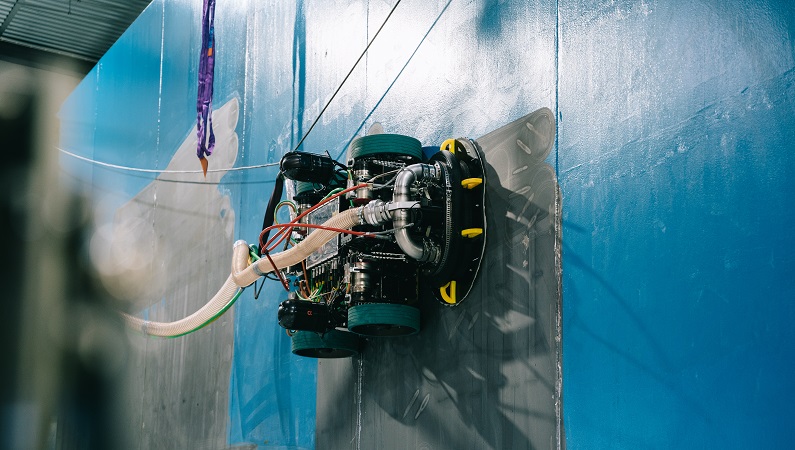

Helios, The Carrier Robot

The heart of the technology is the carrier robot – Helios. This IP68-rated, fully electric, wheel-driven, lightweight magnetic machine can carry a medium load without damaging the surface while maneuvering. With advanced drives and control software, users can operate Helios with great precision.

The RoboCoat Tooling

Helios can equip specialist tools. Remotion team-cooperated with innovative suppliers ˗ experts in the surface treatment industry, to create lightweight and efficient tooling performing diverse tasks in a challenging environment.

Ultra-high Pressure (UHP) Vacuum Blasting

The RoboCoat can be configured with Ultra High-Pressure (UHP) water combined with vacuum suction to remove old coating. A water jet of 40 l/min at 2,700 bar makes the entire process very efficient.

The scrapped coating and blasting water get through a vacuum hose into an onboard filtering unit where the paint particles get separated and waste treated.

Helios’ efficiency is unique and unprecedented. Thanks to its sizeable magnetic holding power, the vacuum tool has a width of 650mm and an efficiency of 60m2 per hour.

Vacuum Grid Blasting

With a vacuum sandblasting head by Pinovo, Helios can grit blast the surface to achieve the required profile. The blasting agents and the dust are transported onto the deck by a vacuum line, where the abrasives get recycled, and the waste is stored. Remotion engineers together with Pinovo developed the grit blasting tool specifically for Helios. The technology features an efficiency of 10m2 per hour.

Coating

We have also developed dust-free, automatic spraying booth for airless spraying. The system features an inbuilt filter and suction to control the spray dust and fumes. The design also includes a two-component pump and advanced control technology. Users can precisely calibrate the tool for the required wet film thickness (WFT).

Other tools

Furthermore, in addition to fabric maintenance tools, Helios can equip NDT tools, manipulators, and mechanical tools.