Remotion developed micro-habitats for Vår Energi

Just before the Christmas holidays, Remotion was approached by Vår Energi, one of the largest exploration and production companies in Norway, to come up with a possible solution to the problem identified onboard one of their FSPOs: several longitudinal cracks in the top section inside a crude oil cargo tank.

The conventional approach would entail repair works conducted at approx. 16-meter height inside a tank filled with hydrocarbons. Such a method would require the construction of 64m2 scaffolding for each location and welding habitats. The repair was estimated to take 800 hours. Such a procedure would put the cargo tank out of service for a long time, reducing the production capacity. Given the situation, Vår Energy needed to explore new solutions for a safe and efficient repair.

At Remotion, we have gained years of experience with cofferdam installations. This technology that can be said to be equal to a welding habitat. However, the underwater cofferdams have one of its important barriers in the differential pressure effect that was not possible in an atmospheric cargo tank. Also, the size of underwater cofferdams was not suitable, given several cracks were near stiffener structures, giving a 90-degree angle to protect.

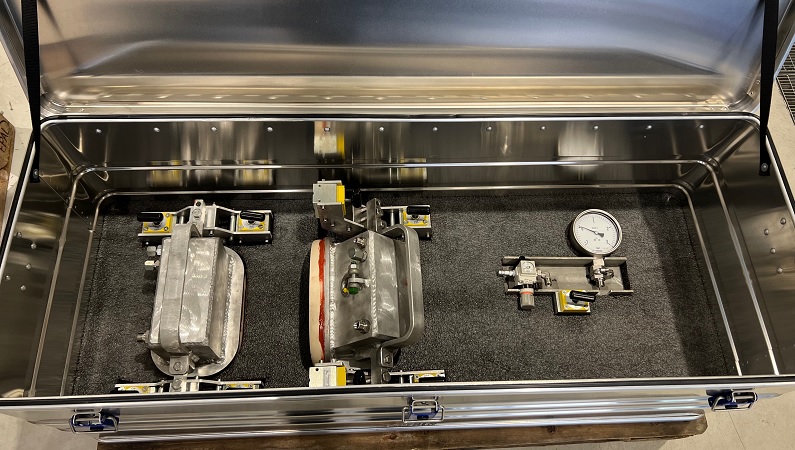

At Remotion, we gathered our multidisciplinary engineering team and highlighted project challenges and possible synergies arising from our existing tools and experience. We came up with a solution: a microhabitat: a welded aluminium structure with special heat-resistant gaskets, 0.005 bar overpressure atmosphere and magnets. Remotion’s engineers designed two models: one for the flat structure and the other for 90 degrees angled structures. Collaborating closely with Vår Energi, our engineering team completed the design phase and detailed engineering. Our long experience and knowledge of production suppliers came in handy when the production had to be divided to achieve the best possible lead time.

Only three weeks after the initial request, the solution passed its FAT test and was sent offshore. The two microhabitats, weighing 9.5kg each, were installed with the assistance of rope access technicians. The repair time totalled 34 hours: a significant saving for our client in terms of time and operational costs.

Remotion is now collaborating with Vår Energi to develop the project further. Working together, soon we aim to install the microhabitats with Proteus Safe – our ATEX-approved robot.